In the competitive world of automotive care, ensuring your vehicle is shielded from the relentless threat of corrosion is absolutely essential for maintaining its longevity and peak performance. Recognizing this critical need, Ziebart embarked on a comprehensive series of laboratory tests to evaluate the effectiveness of their innovative new wax-based undercoating against two of the industry's leading competitor products. The meticulous testing process was designed to simulate real-world conditions and provide an accurate measure of each product's protective capabilities. The results were nothing short of extraordinary, showcasing Ziebart's undercoating as a clear frontrunner in corrosion protection. This groundbreaking performance not only underscores Ziebart's commitment to excellence but also offers vehicle owners a superior solution for safeguarding their valuable investments against the harsh elements.

Rigorous Lab Testing: Ziebart Undercoating vs. Competitors

Laboratory results from the ASTM B117 Salt Spray Test confirmed that Ziebart's wax-based undercoating provided significantly superior protection compared to its competitors. Testing showed that Ziebart's product was dramatically more effective than Competitor A and overwhelmingly outperformed Competitor B. These results emphasize the exceptional protective qualities of Ziebart's undercoating, making Ziebart’s NEW Wax-Based Undercoating the preferred choice for vehicle owners who want to ensure their investment is well-protected with a wax-based product.

Understanding the ASTM B117 Salt Spray Test Method

The American Society for Testing and Materials (ASTM) B117 is a standard test for evaluating the corrosion resistance of materials by exposing them to a salt spray mist. ASTM D610 and ASTM D714 are grading scales used to evaluate the degree of rusting after exposure to ASTM B117.

ASTM B117 Salt Spray Test: Exceeding Corrosion Resistance Standards

The new Wax-Based Undercoating originally passed the test at the standard 1200 hours. Considering how well the undercoating performed, the laboratory technician recommended continuing the test. This test continued for over double the original time, passing with the same score. The test was finally ended at 2700 hours and a score of 9 (representing up to 0.03% corrosion found). The next best competitor coating came in at a score of 6 (representing up to 1% of corrosion found).

Performance in Additional Durability Tests

- SAE J400 Chip Resistance Gravelometer Test: This test simulates the effect of gravel striking exposed surfaces. Ziebart's undercoating scored a 7A, indicating minimal chipping with chips less than 1mm in size.

- SAE J2334 Magnesium Chloride Test: This test evaluates corrosion resistance under severe conditions using magnesium chloride. Ziebart's undercoating passed after 40 cycles and 1000 hours.

- ASTM F2894 High Temperature Resistance Test: Ziebart's undercoating was exposed to 300-degree temperatures and showed no adverse effects.

- Federal Corrosion Specifications: Ziebart's undercoating exceeds MIL-C-0083933A & MIL-PRF-62218B standards, ensuring top-tier protection.

- Multi-State Field Testing: Extensive testing across various conditions confirmed the product's reliability and effectiveness in various climates and regions.

- Undercoating Compatibility Testing: Ziebart's new wax based undercoating formula showed excellent compatibility with their sound deadener undercoating.

Key Features of Ziebart's Advanced Wax-Based Undercoating

- Active Corrosion Protection and Rust Mitigation: Our New Wax-Based Undercoating has active corrosion fighting properties that mitigate rust that occurred before the undercoating was applied.

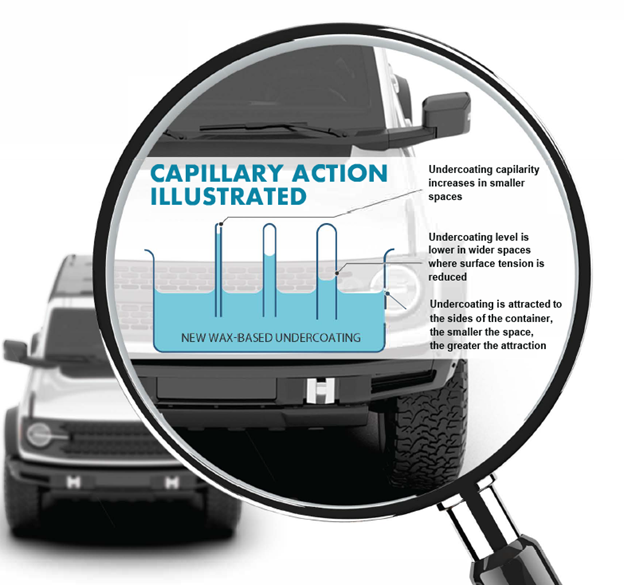

- Self-Healing Formula for Lasting Coverage: This formula is self-healing in the way that it can remain soft and pliable and continue to be active. It’s capillary action and viscous nature will allow it to fill in and cover areas that may have abraded over time.

- Hydrophobic Properties to Repel Water and Moisture: Our New Wax-Based Undercoating is hydrophobic and will displace water upon application. Our undercoating will not trap water or moisture, resulting in a clean and effective application.

- Capillary Action for Complete Protection: This describes the undercoating’s ability to travel in narrow spaces (capillaries) without assistance from external forces, such as gravity. This action allows material to travel to spaces that would otherwise be inaccessible. See below image.

Long-Term Benefits of Ziebart's Wax-Based Undercoating

- Nationwide Limited Warranty*

- Annual Maintenance Program to maintain your vehicle for years to come

- Safe on Electric Vehicles

- Most factory warranties do not cover rust caused by road salt, Ziebart does

- Effective on New and pre-owned vehicles

- Rust Eliminator service on used vehicles with existing rust

- Now Reported to CARFAX and can dramatically increase your vehicles resale value

Protect Your Vehicle Investment with Ziebart

Laboratory Findings: “Ziebart is rated #1 for Corrosion Protection”. For vehicle owners who prioritize durability and long-term performance, Ziebart's wax-based undercoating is the clear choice. The 2025 laboratory testing results highlight its superior protective capabilities, ensuring that your vehicle remains in top condition for years to come. Don't settle for less when it comes to protecting your investment and choose Ziebart and experience the difference. The NEW Ziebart Wax-Based Undercoating is available at select locations, see your local Ziebart for availability.